Precision bearings for medical applications: These factors determine performance and reliability

Precision bearings play a critical role in the medical industry, providing the necessary stability and support for a variety of medical devices and instruments. These components must meet strict specifications regarding performance and reliability to ensure that they can function safely and accurately in the most demanding application conditions. As a result, selecting the right bearings for medical use requires a thorough understanding of various factors that affect their performance and suitability. In this blog post, we will examine some of the critical considerations to bear in mind when choosing precision bearings for medical applications. We will explore the different types of bearings typically used in this industry, their unique features, and how they compare in terms of performance and reliability. Additionally, we will examine factors such as load capacity, speed capability, and temperature resistance that can affect the life and performance of bearings in medical environments. By understanding these critical factors, medical equipment designers and maintenance technicians can make informed decisions about the best precision bearings to use for their applications and ensure that their devices perform optimally for as long as

1. Material selection for bearings is crucial for reducing wear and tear in medical equipment.

Material selection for bearings plays a crucial role in reducing wear and tear in medical equipment. As the healthcare industry continues to advance, the demand for high-performance and reliable bearings in medical applications grows. Bearings are essential components of medical devices, from MRI machines to surgical equipment, and they must withstand rigorous use, often in demanding environments. Choosing the right bearing material is essential for ensuring optimal performance and reliability. Factors such as load capacity, speed, temperature, and corrosion resistance are all critical considerations when selecting bearings for medical applications. By choosing the right bearings, medical equipment manufacturers can achieve longer service life, reduce maintenance costs, and ensure patient safety.

2. Proper lubrication prevents overheating and extends the lifespan of bearings in medical applications.

Proper lubrication is one of the most crucial factors in achieving optimal performance and reliability of precision bearings used in medical applications. Bearings are highly sensitive mechanical components that require a consistent lubrication regime to operate at peak efficiency. Overheating is a common issue that can adversely affect bearing performance and shorten its lifespan. With the right lubrication, friction and wear can be minimized, and an appropriate operating temperature can be maintained, which are essential for reliable and safe operation of medical equipment. By ensuring proper lubrication, bearings can reduce downtime and maintenance costs, improve equipment performance, and ultimately extend their useful life. It's important to select the right lubricant for medical applications that are compatible with the materials used in the bearings, withstand stringent operating conditions, and compliant with regulatory requirements.

3. Bearing clearance can affect performance and reliability, and must be chosen carefully based on the specific application.

When it comes to precision bearings for medical applications, one of the most important factors to consider is the bearing clearance. This refers to the amount of space between the inner and outer bearing races. The correct bearing clearance must be chosen carefully and based on the specific application in order to achieve optimal performance and reliability. For instance, too tight of a clearance can lead to increased friction and heat buildup, potentially causing premature failure of the bearing. On the other hand, too loose of a clearance can result in excessive vibration and noise, which can also negatively impact performance and reliability. It is important to work closely with a trusted bearing supplier who can advise on the appropriate bearing clearance for each individual application, ensuring that the bearings perform consistently and reliably over time.

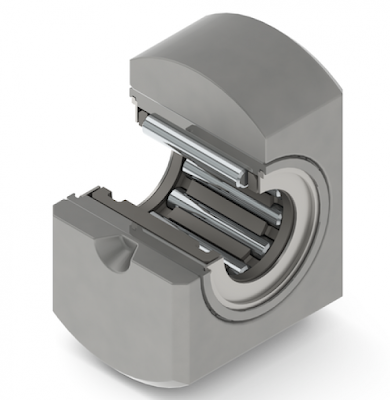

4. High precision bearings are often necessary for medical equipment that requires extremely tight tolerances.

Precision bearings play a crucial role in the performance and reliability of medical equipment that requires extremely tight tolerances. High precision bearings, in particular, are often necessary for medical devices like MRI machines, X-ray imaging systems, and surgical robots. These highly advanced medical devices require the most precise and accurate bearings to ensure smooth and accurate movement, minimizing the risk of errors during procedures. The quality of the bearings used directly affects the level of precision that can be achieved in the medical equipment. Therefore, the choice of bearings for medical applications must be made with consideration to specific medical requirements, such as load capacity, stiffness, and durability, among other factors. In addition, precise engineering, manufacturing, and installation of the bearings are critical to ensure effective operation, enhance patient safety, and minimize maintenance requirements.

5. Regular maintenance and inspection of bearings is necessary to ensure optimal performance and reliability in medical applications.

Precision bearings play a crucial role in ensuring the efficient and reliable functioning of medical equipment. Regular maintenance and inspection of these essential components are critical to meeting the demanding needs of medical applications. Bearings in medical devices are often subjected to extreme conditions, such as high temperatures, corrosive environments, and varying loads, which can lead to wear and tear over time. As such, failure to properly maintain and inspect these bearings can result in expensive machinery breakdowns, significant downtimes, and potentially dangerous situations for patients. To ensure optimal performance and reliability of precision bearings in medical applications, regular maintenance practices, including cleaning, lubrication, and regular inspections, should be adhered to strictly. By doing so, you can minimize the risk of equipment failure, reduce operational costs and downtime, and ultimately ensure the highest level of patient safety and care.

In conclusion, the use of precision bearings in medical applications is critical for ensuring the proper functioning and reliability of medical equipment. When choosing a precision bearing, several factors must be considered, including the type of application, the level of precision required, and the load capacity. It's essential to understand these factors to ensure optimal performance, longevity and, most importantly, patient safety. By keeping these factors in mind and working with a trusted bearing supplier, medical equipment manufacturers can select the right bearings to meet their specific needs and deliver high-quality healthcare.

Megjegyzések

Megjegyzés küldése